Mobiconnect Release Notes V2025.3.1

Inventory Module – (Order Received)

🧾 Feature Overview: Purchase Order Received Management.

- This major release introduces a complete PO Receiving System that supports dynamic order tracking, approval workflows, lot-level customization, and QR code label exports. It ensures accurate material handling, enhanced traceability, and process integrity throughout the inventory lifecycle.

📥 Purchase Order Receiving Workflow

The receiving process now enables complete traceability and structured entry for every item delivered:

-

Itemized Material Receiving: Receive line items partially or fully as per vendor delivery. Enter received quantity, validate against order, and attach documentation.

-

Auto-Filled PO Details: Material data is automatically fetched from the PO including ordered quantity, unit of measurement, vendor, and expected delivery date.

-

Staggered Delivery Support: Handles multiple deliveries under the same PO, updating only relevant quantities.

-

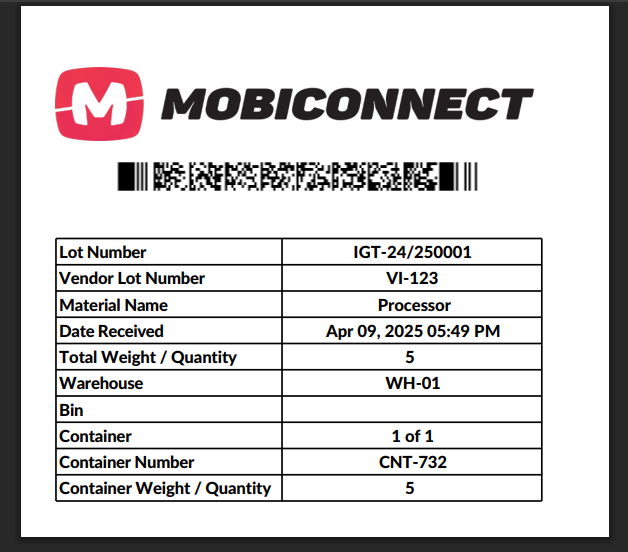

QR Label Export for Each Lot:

-

After a lot is received, users can generate and export QR-coded labels.

-

Each QR label links to the system’s lot data — including material code, batch number, and quantity.

-

Labels can be printed and attached to physical stock for easy scanning, traceability, and warehouse organization.

-

Here is a complete demo of materials module which highlights Purchase Order Received module.

🔄 Dynamic PO Status Tracking

The Purchase Order module now features intelligent and customizable status management to reflect real-world receiving workflows accurately:

| Default Statuses | Meaning |

|---|---|

Pending |

No items have been received yet. |

Partially Received |

At least one item received; remainder is pending. |

Received |

All PO line items have been completely received. |

Rejected |

PO was closed without fulfillment or has been manually terminated. |

🔧 Custom Status Configuration

-

In addition to system-defined statuses, users can now create their own custom PO statuses via the Settings module.

-

Each custom status can be:

-

Named based on your internal terminology (e.g., Quality Hold, Awaiting GRN, Under Inspection).

-

Color-coded for visual distinction in dashboards, reports, and most importantly — QR label exports.

-

-

These statuses can be applied manually or linked to specific conditions (optional, based on configuration).

🌈 Status Colors for QR Labels

-

When exporting QR-coded labels for received lots, the assigned status color is included visually:

-

Helps warehouse or inspection teams instantly identify item state from the physical label.

-

Supports faster segregation, sorting, and action-taking in high-volume environments.

-

This makes your system not just informative — but highly visual and adaptable to any operational flow.

🛡️ Order Received Approvals

To ensure only verified items enter inventory, a configurable approval system is built into the receiving process:

-

Department-Specific Routing: Approval flows are determined based on the originating department of the purchase.

-

Assigned Approvers: Approvers are assigned from the Settings module and notified automatically.

-

Multi-Tier Approval Support: Allows sequential or parallel approvals based on configuration.

-

Stock Lock Until Approval: Inventory updates are held until approvals are completed, ensuring only verified items are counted.

-

Audit Logging: Every approval or rejection is logged with time, approver identity, and remarks.

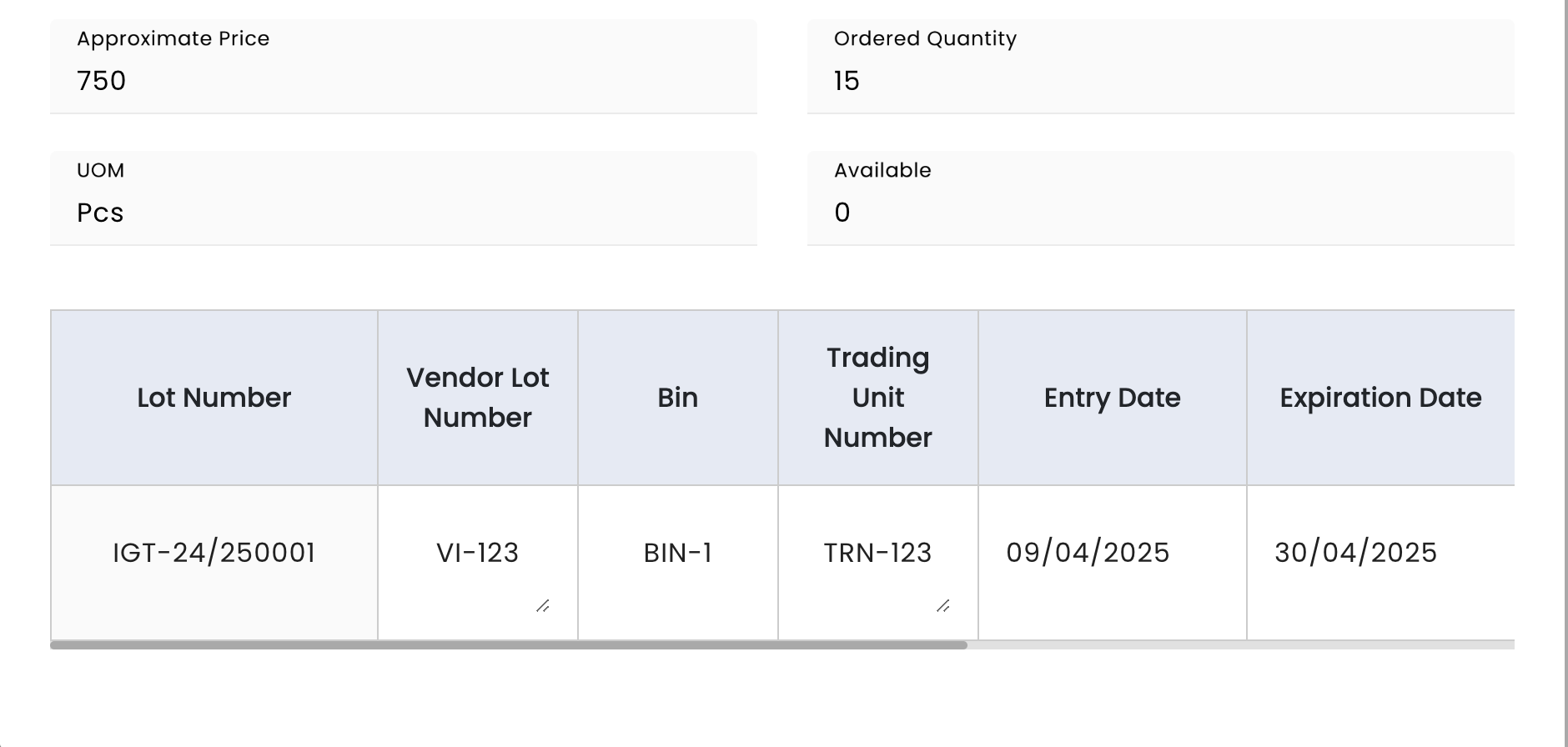

📝 Lot-Level Data Capture with Dynamic Fields

Capture complete and customized data for each lot received:

-

Admin-Defined Fields: Create and manage dynamic fields from the Settings panel — including text inputs, dropdowns, dates, numbers, and checkboxes.

-

Lot-Based Entry: Fields appear during receiving for each item or batch, supporting use cases like:

-

Batch No.

-

Expiry Date

-

Manufacturer

-

Quality Grade

-

-

Flexible Data Structure: Allows industry-specific tracking (e.g., pharmaceuticals, perishables, or manufacturing).

-

Exportable Records: All field data is stored, reportable, and included in exports.

🧾 Attachments, Notes & Document Support

-

Upload Support Files: Add GRNs, delivery notes, inspection reports, or invoices during receiving.

-

Material Notes: Enter quality concerns, shortages, or visual flags for downstream teams.

🛠️ System Enhancements

-

Over-Receiving Prevention: Validates quantity limits based on PO.

-

UI Improvements: Streamlined receiving form with inline validations and prefilled data.

-

Live Stock Sync: Upon approval, received quantities are synced to inventory.

-

Advanced Filters: Filter PO receipts by vendor, material, approval status, department, or date.

🔔 Notifications & Settings

-

Email Alerts: Triggered on receipt, approval pending, approval done, or rejection.

-

SMS Integration: Optional SMS alerts available via Twilio.

-

Complete Audit Logs: Every user action is recorded with timestamp and user ID.

🔐 Security & Compliance

Your Purchase Order Receiving workflow now includes key safeguards to ensure data integrity, user accountability, and audit-readiness — crucial for regulated environments and enterprise-scale inventory management.

🧾 User Role-Based Access Control (RBAC)

- Only authorized roles (e.g., warehouse, inventory manager, or approver roles) can perform actions such as:

-

-

Creating or editing received entries

-

Approving or rejecting received lots

-

Exporting QR labels or documents

-

-

Permissions can be finely tuned in the admin panel to restrict visibility or actions by department, user level, or module scope.

📚 Full Audit Trail & Activity Logs

-

Every transaction in the PO Receiving lifecycle is automatically logged, including:

-

Material received (what, how much, when, by whom)

-

Status changes (including custom status updates)

-

Approvals or rejections with timestamps and user details

-

-

Logs are non-editable and can be exported for compliance audits.

🗂️ Document and Data Retention

-

Uploaded delivery notes, invoices, and GRNs are securely stored and linked to the corresponding receiving entry.

-

Dynamic field data (e.g., batch no., expiry, custom values) is retained permanently with each lot for traceability and historical reporting.

🔍 Tamper Protection

-

Once a lot has been approved and marked as received, the data is locked from further modification (unless rollback permission is explicitly given).

-

Any modifications post-approval trigger alerts and require justification with user tracking.

🔒 Data Security

-

All receiving data is transmitted over secure, encrypted connections (HTTPS).

-

Backend data is protected with database-level encryption and automated backups to prevent data loss.

📈 Business Impact

This release brings significant automation and transparency to your procurement process. Teams can now:

-

Foolproof Receiving: Ensures correct items are received, verified, and recorded.

-

Full Traceability: QR labels, custom lot data, and audit logs make tracking easy from vendor to stockroom.

-

Process Compliance: Approval flows ensure accountability and data security.

-

Adaptable Design: Works for small teams or enterprise warehouses, configurable to your exact needs.

This update provides an end-to-end digital workflow for purchase order fulfillment — from vendor delivery to warehouse shelves, with total transparency and control with a seamless stock control like never before!

If you need a hand you can always reach out and raise a tech support ticket at support.mobiddiction.com

Enjoy Mobiconnect™[/vc_column_text][/vc_column][/vc_row]